Making greenhouses greener by making them magenta

Two physicists are using their research to bring a new color and solar power to greenhouses, making them an even more environmentally friendly option for farming, finds Bailey Bedford. Illustrations by Nick Bezio and Elena Hartley.

Illustration: Nick Bezio

On an overcast winter day, an eye-catching pink pops in a corner of the parking lot at the UC Santa Cruz Arboretum & Botanic Garden. The striking neon magenta hue emanates from the walls and ceiling of a small greenhouse. Inside the greenhouse, the red tint lends the small space an alien feel, and black cables hang down from the ceiling. The greenhouse is the prototype of a new type of solar-powered greenhouse that generates electricity to make the greenhouses more profitable and environmentally friendly.

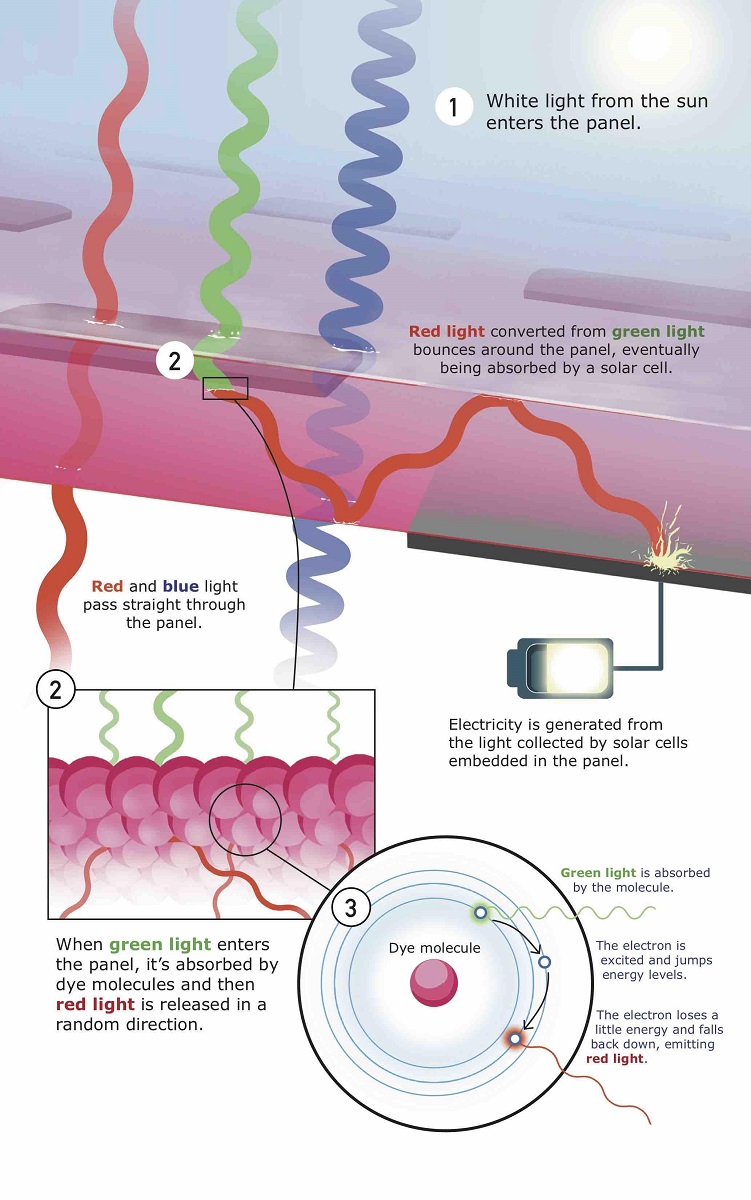

The magenta panes are more than colored windows; they actually glow slightly at the edges. When the material was put up on a commercial farm in Watsonville, Calif., a neighbor commented on the eerie glow coming off the greenhouse under the light of the full moon. The glow is the result of the panes being a type of solar panel, called a luminescent solar concentrator, that changes one color of light to another as part of the process of collecting light to produce electricity. They absorb the green portion of white light and release it as red light. White light, like that from the sun or moon, contains all the colors of light. Plants are green because the green portion of the light is reflected instead of being absorbed like the other colors, which is why the panels were designed to harvest it. Researchers are testing and deploying these magenta panels in farm greenhouses.

Sue Carter, a physicist at the University of California, Santa Cruz, is one of the researchers behind these panels. The panels bright color is the result of harvesting most of the green light to produce clean electricity while allowing other colors of light through to nourish the plants. By collecting green light with innovative technology and supplying plants with blue and red light , Carter hopes that farmers can help meet clean power demands while still growing a healthy crop.

“I think this technology is a really good example of when people try to envision the future where you have renewable energy sort of everywhere,” said Lance Wheeler , a researcher at the National Renewable Energy Laboratory who develops materials for solar technology.

The growing demands for agricultural land and sustainable power production are pushing humanity to search for creative solutions to how we harvest food and energy. A 2012 report from the Food and Agriculture Organization of the United Nations suggest that by 2050 to feed the growing world population we may need to be growing crops on 70 million hectares more land, which is more than three times the area of Kansas. While this increase is not impossible, much of the land may not be near infrastructure or markets where it is convenient or practical to use. Solar power also requires land near infrastructure and markets. If we can combine the two land uses, it minimizes the negative environmental impacts of clearing of land for human use.

Carter set out produce clean, cheap electricity and ended up discovering a potential way to combine these land uses. She and her husband have commercialized panels that can allow such combined land use through the company Soliculture. Soliculture is currently focusing on farms in California and Ontario, Canada that already have many greenhouses and high electricity costs. They have installed the technology on farms, like Freeman Herbs in Ontario, Canada and Whiskey Hill Farms in Watsonville, Calif., and are working to expand to additional markets. In addition to producing food, the technology may be used with growing other products like flowers and cannabis.

Since before she was a professor, Carter wanted to pursue practical applications for her physics research, but she didn’t begin her career with a plan to revolutionize farming. Early in her career she used organic materials to make small lightbulbs, called LEDs , that efficiently turn electricity into light and may now be found in modern flat-screen televisions. Eventually, a student who was passionate about climate change encouraged her to investigate using inexpensive organic materials for the reverse process — turning light into electricity.

Carter began working on organic solar technology. Since the early 2000s, researchers have investigated using organic materials in solar technology due to potential advantages like cheapness and ease of fabrication. But around 2010, the drop in the cost of silicon and the growth of the Chinese solar industry lowered the cost of solar technology based on silicon. According to a report from the International Renewable Energy Agency, prices of photovoltaic solar panel modules, most of which were silicon-based, decreased by about 75 percent between the end of 2009 and the end of 2014.

A colorful solution

Instead of abandoning using organic materials to help produce clean energy, Carter pursued using organic materials in an innovative type of solar technology, luminescent solar concentrators. Organic dyes can be used to manipulate light in luminescent solar concentrators. Luminescent solar concentrators are transparent or semitransparent sheets that can direct certain colors of light to solar collectors while letting other colors pass through. They aren’t as efficient as traditional solar panels since they are not collecting as much light, but allowing light to pass through makes them promising for specialized applications like turning tinted windows into a source of electricity. Carter’s lab worked to find if they could make a long-lived dye that would absorb a color that would work for a practical application and to efficiently guide the transformed light through the panel.

For practical applications, luminescent solar concentrators and other solar technology require an investment in infrastructure and space to install it, so Carter and her colleagues looked for applications where the panels could use existing structures. Additionally, normal solar panels would shade plants beneath them hurting their growth, but luminescent solar concentrators can collect light for power generation while still providing plants with diffuse light in the colors that they need. So luminescent solar concentrators have unique advantages for applications with greenhouses.

Carter and her husband Glenn Alers, who at the time was also a physics researcher at the University of California, Santa Cruz, decided to work on luminescent solar concentrators that used a dye which mostly absorbs green light and allows most of the blue and red light that plants use to pass through. The discovered dye and technology were not revolutionary for the field , but they recognized that it could be uniquely suited for use with agriculture and engineered a product for that purpose. Alers left academia to start the company Soliculture and focus on turning the technology into a commercial product for greenhouses. Carter remained a professor but has collaborated with Soliculture on research and is the company’s chief financial officer and is on the board of directors.

The panels have strips of solar cells in about a quarter of the area of the greenhouse panels so that light passes through while much of the unneeded, originally green, light is directed to the strips of solar cells to produce more electricity. The panes can be installed in the normal frame of a greenhouse, which can make installing the solar panels cheaper.

This design works because when light enters one of the special panels, the green light and some of the blue light interact with the proprietary organic dye that is embedded in the plastic. That dye absorbs the energy from the light, temporarily storing the energy in the electrons of the dye’s atoms. But there is nothing to keep the energy tied to those electrons, so the electrons lose a little energy, generating heat, and then quickly lose the rest of the energy by returning to their previous states. This remaining energy is released as light. The new light is red and travels in a random direction.

This sort of transformation of the color of light is the science behind fluorescent colors. It is what gives neon traffic cones their vibrant pop. When light hits the cones, a fluorescent pigment in the cones produce extra orange light. The cones appear so bright because there’s more orange light coming off them than hitting them.

“Physicist don’t know how to grow plants,” said Carter. “I can’t tell you how many plants we killed off.”

In the greenhouse panels, this process gives the panels a Tron-like neon hue, and helps them produce more electricity. Since the new red light generated by the panels travels in a random direction, most of it doesn’t go straight back out of the panel. It bounces between the two surfaces of the panel until it hits a solar cell embedded within the panel. The solar cell converts the collected light into usable electricity.

In Carter’s lab, boxes of small, colored samples made to test various dyes and panels propped against a wall with the strips of solar cells laid out in different patterns, including zigzags, nested squares and grids, testify to the experimental work that went into the panels. Soliculture ended up compromising on a checkerboard pattern as the best compromise of efficiency and being practical to commercially fabricate.

Learning how to get physics into the field

In addition to optimizing the design of the solar cells, Soliculture had to show that the panels work with plants and meet farmers’ needs. They created a small greenhouse on the University of Californian, Santa Cruz campus. They grew plants in it as if they were gardening in their backyard.

While typical commercial greenhouse tomato plants can be over 25 feet long, their tomato plants only reached four or five feet long. The data from a thousand square foot greenhouse is not useful for learning about effects in an acre greenhouse because the size of the plants and the climate control are significantly different. “The commercial greenhouse growers basically laughed at us, at our attempt to be growers,” said Alers.

“Physicists don’t know how to grow plants,” said Carter. “I can’t tell you how many plants we killed off.”

The team had to learn the importance of techniques like trimming tomato plants and growing plants in nutritious solutions instead of soil from the farmers in order to grow plants well. When installing the magenta material, students on the project even had to be corrected on what was the top and bottom of a ladder. Working with commercial growers at Kitayama Bros Inc. in Watsonville, Calif., helped them develop the technology using more realistic conditions. “I use to tease them a little bit that they were like rocket scientists but they weren’t really plant scientists,” said Carol Kitayama, who help the physicists transfer their technology to her commercial farm. “They didn’t know a lot about the growing.”

Also, plants don’t just interact with light through photosynthesis. Light can influence a plant’s development and nutrient content. For instance, blue light has been observed to influence the opening of pores on plants and changing the color of light can change a plant’s antioxidant content. Christian Fankhauser, a molecular geneticist at the University of Lausanne who studies how plants interact with light, believes Soliculture’s technology is “quite promising” if the effects of the light are carefully investigated and the nutritional values are maintained. For instance, the level of antioxidants, like lycopene that makes tomatoes red and that some people think has health benefits, could be altered, he says.

Showing farmers that the change in the light doesn’t negatively affect the crop yield or quality for any new operation is a major part of Soliculture’s work. Alers says Soliculture has shown the panels to be compatible with growing several varieties of tomatoes, cucumbers, lettuce, peppers and flowers. While they have measures yield and basic micronutrients like sodium, nitrogen and calcium for crops grown with their panels, they do not test for more complex compounds, like antioxidants. Alers does not believe there is an impact on secondary compounds and does not believe that growers or most consumers care about them. “For the flower industry, they don’t really care,” noted Carter. “As long as we don’t cause it to bloom too early. If the bloom period gets off by a week, we just hosed Mother’s Day,” she says with a laugh. “That’s not good.”

Hunter McDaniel is the founder and CEO of UbiQD, Inc., a company that developed greenhouse panels that optimize the color of light for growing plants but don’t produce electricity. He believes that products like his company’s panels and Soliculture’s luminescent solar concentrators are the future of greenhouses. He suggests that a big technological hurdle for Soliculture’s application is ensuring that the organic fluorescent dyes they use will last for a long enough time. The dyes would be worthless if they break down from exposure to light and stop producing electricity before they have produced enough power to pay for themselves. This is especially a challenge because if Soliculture discovers that a certain crop needs a different color of light to thrive, an entirely new dye would be required. Many organic dyes will not keep working for many years in a practical setting.

Soliculture treats the dyes and materials they use as proprietary information, so how they have achieved a stable dye is not publicly known. While the lifetime of the panels has not been proven through multiple decades of practical use, Alers believes the panels will last based on them having passed International Electrotechnical Commission tests to ensure their quality and tests equivalent to 25 years of exposure to ultraviolet radiation. “We are totally confident in the long-term stability of these, which is why we have a warranty for 25 years,” said Alers.

A growing market

Soliculture has about 50,000 square feet of greenhouses currently covered by their panels according to Alers. There is still plenty of room to expand. According to the most recently released U.S. agricultural census there was over 2 billion square feet of crops grown under glass or other protection in the U.S. in 2012 , and according to a report from Alberta’s Ministry of Agriculture and Forestry there was over 256 million square feet of commercial greenhouses in Canada in 2015.

“I am very excited that we have gone from this at UCSC,” said Alers, holding up a sheet-of-paper-sized panel with glowing red edges, “to that,” with a gesture to the man-height current model of panel crowding one corner of the office. “That is a pretty major accomplishment.”

Soliculture is investigating using the panels in the cannabis industry with promising results, according to Alers , and is also developing a design for use over fields of low-lying crops, like lettuce and strawberries without interfering with their growth or harvest. Carter is continuing to perform research that might make the future luminescent solar concentrators cheaper and better. Finding long-lived dyes that efficiently absorb invisible infrared and ultraviolet light could help generate a little more power.

Dyes discovered in Carter’s lab may one day cast a rose-colored hue on crops from strawberries to cannabis and help humanity keep its footprint manageable.

© 2019 Bailey Bedford / UC Santa Cruz Science Communication Program

Bailey Bedford

Author

B.S. (physics) University of Oklahoma

M.S. (physics) Pennsylvania State University

Internships: Eos, the Monterey Herald (Monterey, CA), Inside Science, Fermi National Accelerator Laboratory (Batavia, IL)

As a child, I loved hearing and telling stories, but I struggled with spelling and reading. Then, when I was nine years old, I discovered the Harry Potter books. Captivated by these adventures and mysteries, I began reading on my own. After that, I plowed through books, even taking them out to the playground to read during recess. Later, a diagnosis of dyslexia helped me understand my struggles and improve my spelling and study habits.

Science was always another story I couldn’t put down, which led me to a physics graduate program. As a teaching assistant, I gained a deeper appreciation for how to use a good story to educate. Now, I strive to both captivate my audience and help them understand the complex world around them.

Nicholas Bezio

Illustrator

B.S. (marine biology) Roger Williams University

B.A. (environmental chemistry) Roger Williams University

Internship: Dr. Allen Collins, Smithsonian National Museum of Natural History, Invertebrate Zoology Department

Born and raised just outside Burlington, Vermont I’ve always been fascinated by the diversity of

invertebrates and the alluring beauty of the ocean. It was during my years at university that I rediscovered

my love of drawing as well as my obsession with jellyfish and comb jellies. Over the next couple of

years, I would work on publishing a manuscript, study at The Marine Biological Laboratory, and even

have access to scientific manuscripts made over several centuries ago. It was looking at these old

manuscripts – many of them lacking any visuals – that convinced me to apply and graduate from the

Science Illustration program at CSUMB.

Elena Hartley

Illustrator

B.A () Oberlin College 2018

Internship: Science illustrator intern at Environmental Systems Research Institute (Esri), Comic panel artist on We Can Do It, Part 2

ELENA HARTLEY is a science illustrator from Atlanta, GA who, in addition to drawing, loves rocks, atoms, photons; the things that make up the world. While a student at Oberlin College, she became inspired to pursue science illustration during her tenure as the art coordinator of The Synapse Magazine, a student science publication that bridged art and science. As a visual learner herself, Elena understands how vague and complex science can be when described with only words. Now, she strives to make science more understandable by making it accessible with illustrations.

Outside of science illustration, Elena writes comics, designs creatures and collects rocks.

Where can I buy them?